Menu

PROVOKE™ FEATURES

Built Around Human Factors and Ergonomics

Provoke ligament knee brace is designed and engineered around each leg and patient’s needs, with the goal to maximize comfort and increase mobility. Combining high-performance aircraft-grade Polyamide 2200 material with software-aided design, an ultra low-profile frame design, a hinge that tracks the natural motion of the knee, and the lightest engineered rigid ligament knee brace in the world, the Provoke is unlike any other types of knee brace.

SCAN-TO-FIT PROCESS

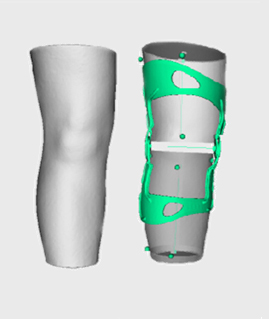

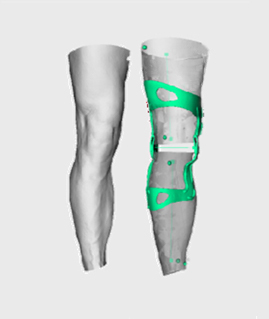

Digitally modelized for a perfect fit on any leg shape and for greater control

The Provoke ligament knee brace is digitally modelized and personalized for each leg shape using OssKin’s proprietary software. This allows for an ultra-precise fit to any morphology and total surface contact for extra comfort and control. Once modelized to an individual leg, the brace parts are 3D printed in state-of the art machines used in the aerospace and medical industry.

PROVOKE™ SPECS

Provoke™, an SLS 3D-printed knee brace for ligament deficiencies

Provoke is truly custom and digitally designed and 3D-printed for each individual patient’s leg that seeks to protect the knee’s deficient ligament throughout the three anatomical planes of movement without collateral effects. It features OssKin’s patented Asymmotion hinge system, that tracks the natural tridimensional motion of the knee thus not hindering the leg’s mobility.

INDICATIONS

The Provoke functional knee brace is more than a simple customizable knee brace. It is specifically personalized to cater to various ligament conditions. It is especially beneficial for individuals who experience:

- Torn Anterior cruciate ligament (ACL)

- Torn Medial collateral ligament (MCL)

- Torn Lateral collateral ligament (LCL)

- Torn meniscus

- Knee ligament injury and chronic knee ligament instability

DOCUMENTS

SLS 3D-PRINTED

Provokeᵀᴹ parts are SLS 3D-printed using state-of-the-art equipment used by the aerospace industry

The Provoke knee support is digitally modelized and personalized for each leg shape using OssKin’s proprietary software. This allows for an ultra-precise fit to any morphology and total surface contact for optimal comfort and control. Once modelized to an individual leg, the brace parts are 3D printed in state-of the art machines used in the aerospace and medical industry.

Customer Support

Get in touch to learn more about the most innovative knee brace on the market.

Follow Us