Evoke™

The world’s first SLS 3D printed custom

unloader knee brace

THE WORLD’S LIGHTEST BESPOKE

KNEE BRACE

CUTTING-EDGE PATENTED HINGE SYSTEM

THE WORLD’S FIRST 3D PRINTED KNEE BRACE

EVOKE™ FEATURES

Built Around Human Factors and Ergonomics

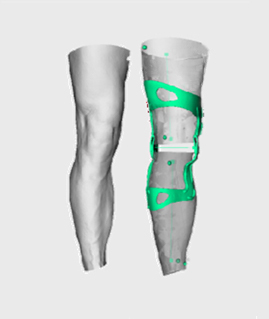

Evoke unloader knee brace is designed and engineered around each leg and patient’s needs, with the goal to relieve knee pain and increase patient’s level of daily activities. Evoke is digitally modelized using our proprietary mass customization software and then individually 3D-printed with aircraft-grade Polyamide 2200 material. It features an ultra low-profile frame design, a hinge system that tracks the natural motion of the knee, and is the lightest engineered rigid knee brace in the world.

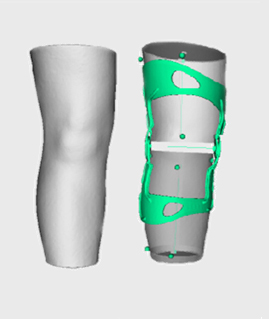

SCAN-TO-FIT PROCESS

Digitally modelized for a perfect fit on any leg shape and for greater control

The Evoke unloader knee brace is digitally modelized and personalized for each leg shape using OssKin’s proprietary software. This allows for an ultra-precise fit to any morphology and total surface contact for extra comfort and control. Once modelized to an individual leg, the brace parts are 3D printed in state-of the art machines used in the aerospace and medical industry.

EVOKE™ SPECS

Evoke™, an SLS 3D-printed unloader brace

The Evoke knee brace is truly custom and digitally designed and 3D-printed for each individual patient’s leg, aiming to provide pain relief from osteoarthritis and help regain full range of motion. It features OssKin’s patented Asymmotion hinge system, that tracks the natural tridimensional motion of the knee, ensuring unrestricted leg mobility.

INDICATIONS

The Evoke custom knee brace is designed to address a range of conditions. This type of knee brace is particularly suitable for patients with:

- Knee osteoarthritis – mild to severe

- Knee conditions requiring load reduction and redistribution

- Torn meniscus

DOCUMENTS

CLINICALLY PROVEN

Evoke delivered unparallel scientific results for ultimate patient outcome

The Evoke unloader knee brace has been scientifically tested in numerous clinical studies in collaboration with world-class Orthopedic Research Centers and University Engineering Research teams. Using state-of the art testing technology, such as Vicon motion sensors and 3D-planar X-ray technology, combined with robust and unbiased scientific protocols, the Evoke knee support has achieved positive results in providing the patient with greater mobility, needed unloading, and increase in daily activity levels.

Looking to Get Fitted with an OssKin Brace?

Simply fill out this form, and we’ll help you find the nearest clinic to you.

SLS 3D-PRINTED

Evokeᵀᴹ parts are SLS 3D-printed using state-of-the-art equipment used by the aerospace industry

The Evoke knee brace is digitally modelized and personalized for each leg shape using OssKin’s proprietary software. This allows for an ultra-precise fit to any morphology and total surface contact for extra comfort and control. Once modelized to an individual leg, the brace parts are 3D printed in state-of-the-art machines used in the aerospace and medical industry.

Customer Support

Get in touch to learn more about the most innovative unloader knee brace on the market?