Home > Innovation and Tech > 3D-Printed Knee Brace VS Traditional Knee Brace

There are a large variety of knee braces on the market, each with its own unique characteristics. For over 100 years, orthotics have evolved considerably to better support the knee and relieve pain, especially with the more recent adoption of 3D printing.

What are the main differences between traditional orthotics and 3D-printed orthotics?

We explain everything in this article!

Traditional orthotics are not “made to measure” and do not have a lengthy manufacturing process. Some traditional orthotics can even be purchased directly from a clinic with a prescription from the patient’s family doctor. Traditional orthotics can be effective when the patient needs one quickly, as they are not customized and are already made.

However, one of the downfalls of traditional orthotics is that they can sometimes be heavy due to the different materials used, whether that is plastic, metal, leather, or fabric. Additionally, orthotics are manufactured using traditional methods such as hand-molding or machining, so some specific shapes or designs may be difficult to achieve using traditional manufacturing techniques.

Those considering traditional orthotics must also realize that because they are not custom-made, they can sometimes cause migration on the patient’s leg, meaning e.g. the orthotic may be too large or may fit incorrectly.

3D-printed orthotics have been a major advance in the past several years in the field of orthotics. They enable greater precision in design, thanks to the scans and reference points used on the patient’s leg. These fully digital processes save clinicians time in modeling and creating the orthosis.

Personalization of the orthosis combats one of the challenges of traditional orthotics in that it considerably reduces migration. This offers support adapted to each patient’s morphology and pathology. Customization can even extend further than the personalized structure sometimes, as there may be the option to select colors or patterns.

The use of 3D printing makes it possible to use lighter materials than traditional orthotics, minimizing the bulkiness. As a result, the orthosis is more discreet, so patients can easily put them on under their pants or dresses and wear them more comfortably long-term in the case of chronic pain.

The use of polyamide 2200 in 3D-printed orthotics not only ensures very high resistance to wear and tear, but also offers a superior level of strength, rigidity, and toughness compared to the plastic materials found in traditional orthotics.

OssKin has been offering 3D-printed knee orthoses since 2016, providing relief for people suffering from osteoarthritis or cruciate ligament injuries.

The 3D-printed Evoke orthosis relieves osteoarthritis pain by reproducing the knee’s natural movement, thanks to our Asymmotion™ helical hinge system. This unique mechanism reproduces internal and external rotation, abduction and adduction, as well as anteroposterior and vertical knee movement.

The movements of the medial and lateral condyles are asymmetrical, hence the “screw home” mechanism of the knee that involves frontal and sagittal plane movement. Thanks to OssKin’s asymmetrical articulation system, the Evoke brace is the only knee brace that perfectly reproduces both sides of this movement.

The brace can be used to relieve various types of osteoarthritis—whether mild or severe—meniscus tears, and knee conditions requiring load reduction and redistribution.

OssKin orthotics are manufactured by an additive manufacturing process. Layers of polyamide powder are fused using a laser to produce a dense, rigid material.

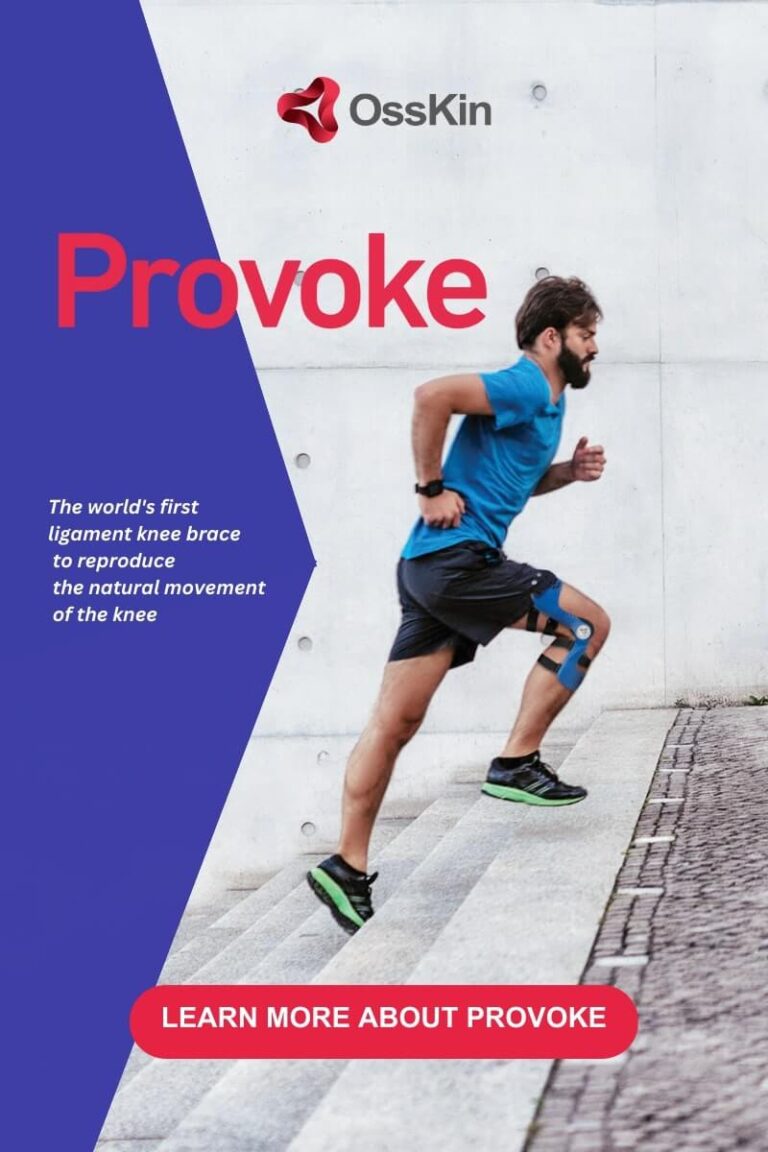

Provoke is another orthotic model from OssKin, with the same features as Evoke, but specialized for patients with cruciate ligament problems. Provoke facilitates the natural axial rotation of the knee thanks to the Asymmotion™ Hinge System. However, it also protects and limits it from excessively rotating. With 3D modeling and Provoke’s anterior tibial cuff design, the Provoke conforms to the triangular anterior shape of the tibialis, thus obtaining a better grasp and control of the tibia.

Share on

OssKin © 2024